The Hybrid Safety Valve Straddle System was developed to overcome the limitations of WRSSSV systems, boasting a unique sealing system that expands into the seal bore providing many operational benefits.

KEY FEATURES

- As the seals run 'under gauge' this virtually eliminates risk of damaging seals during installation

- Simultaneous seal energisation enables purging of control line

- Can be retrofitted and used with any OEM WRSSSV

- Contains a Dual Isolation Bore Seal System (patented GB2586537)

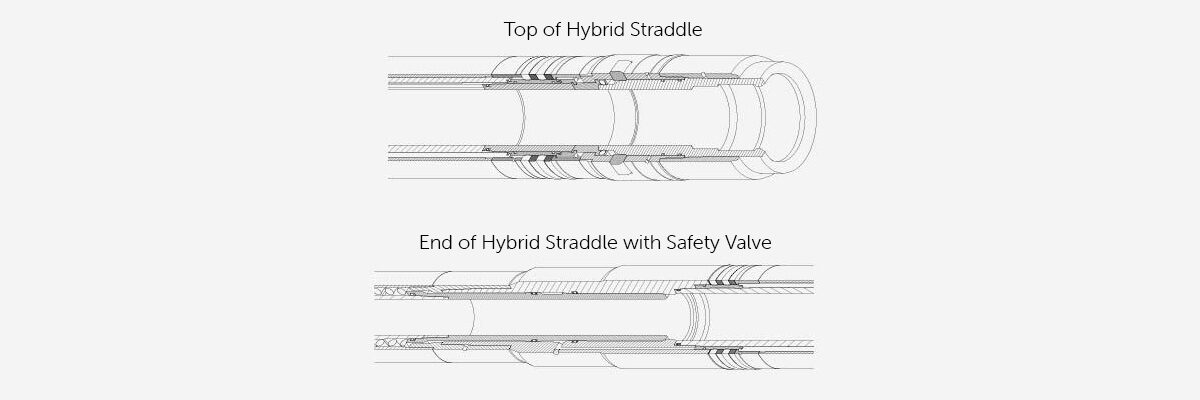

HOW IT WORKS

The Hybrid Safety Valve Straddle is deployed on slickline into the well and located inside the downhole safety valve. The seals, being under-gauge, are free to pass the upper and lower seals bores of the downhole safety valve allowing the Hybrid Straddle to land off at the nipple no-go.

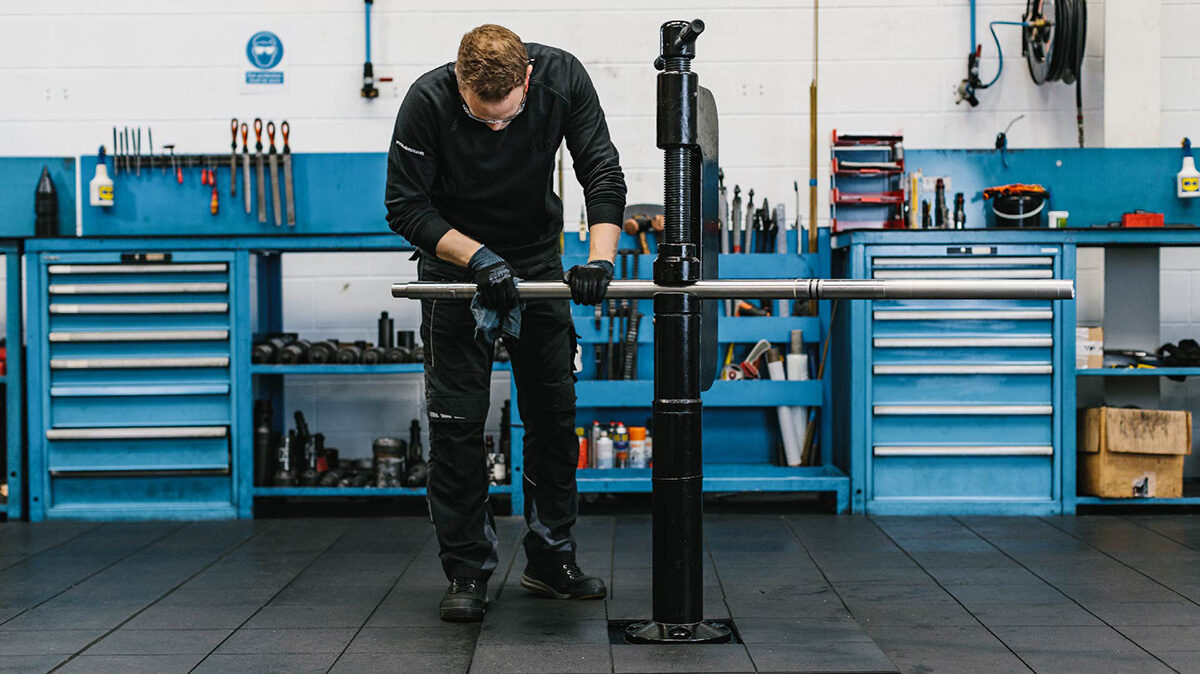

Following flushing of the control line, light downward jarring will set the Hybrid Straddle. During the setting sequence the lock dogs are located into the corresponding nipple key profile. Next the top and bottom set of dual sealing elements are expanded simultaneously into the seal bores, thereby instantly isolating the safety valve control line system. Further jarring releases the running tool. It is then possible to pressure up the control line and open the wireline retrievable safety valve.

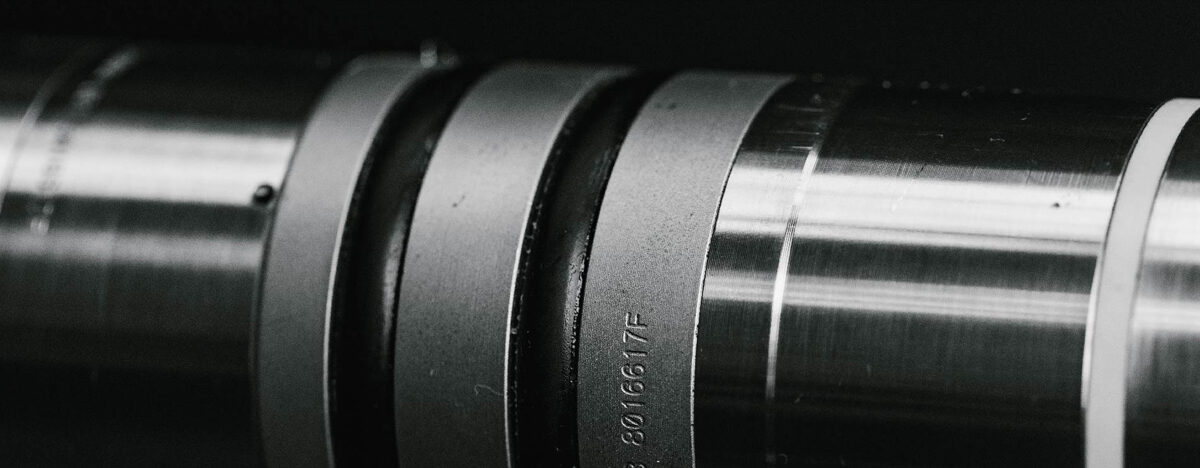

UNIQUE SEALING SYSTEM

The Hybrid Safety Valve Straddle system features an upper and lower set of expanding seals that are interconnected by a mechanical linkage system. As a result, both the upper and lower seals expand into the centre of the target seal bore simultaneously, potentially improving sealing capability in a damaged seal bore.

When run into the seal bore the diameter of the seal is less than the diameter of the straddle, known as running 'under-gauge'. This means the straddle lands on the profile no-go without the need to force the seals into the target seal bore. This feature virtually eliminates the risk of damaging the seals as they are naturally protected.

A wiper seal is positioned immediately below the lower set of expanding seals to provide a temporary seal below the lower seals of the straddle. This allows pumping of hydraulic control line fluid to flush out any residual, trapped gas within the control line. An exit port sits above the upper seals of the straddle allowing excess fluid to escape. In this way the control line can be fully purged to ensure clean hydraulic fluid. Once in position inside the TRSSSV the seals are then energised and expand into the seal bores simultaneously.

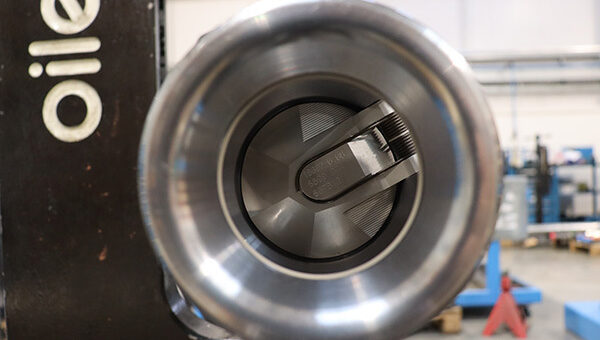

The Hybrid Straddle system is compatible with existing OEM supplied wireline retrievable safety valves or can be paired with the Oilenco wireline retrievable safety valve.

For more information on the Hybrid Safety Valve Straddle System, contact the Oilenco team on +44 (0)1224 548700, email info@oilenco.com or click the 'Enquire Now' button below to complete the enquiry form.